Analysis of advantages and disadvantages of marble stairs and granite stairs

2019-09-11

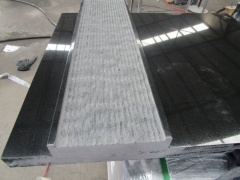

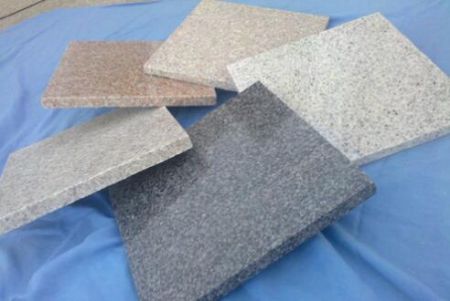

First, the marble staircase A good marble staircase reflects the decorative style of the whole house. Low-key without losing luxury, noble is not restrained. The pen and ink are indescribably magnificent. Whether it is a villa, a duplex building, or a self-built house, the stairs are an essential part. How to design a beautiful and practical staircase is a highlight of the living room. In addition to special attention to its design (spiral, straight, rotating, floating, etc.), the marble staircase needs to pay attention to its consistency with the overall style of the house. At present, the trend of interior design tends to be more and more refined, sometimes even purely minimalist. Advantages of marble-decorated stairs: 1. No deformation, high hardness and strong wear resistance. 2, no odor, corrosion resistance, high temperature, maintenance-free. 3, physical stability, fine organization, the surface of the impacted crystal does not burr, does not affect its plane accuracy, material stability, long-term deformation, small linear expansion coefficient, high mechanical precision, anti-rust, anti-magnetic, insulation. 4. Easy to maintain. Black soap diluted with water can solve the problem of cleaning marble surfaces, avoiding the use of acidic products, chemicals, bleaches! Since marble is easy to see stains, it must be maintained regularly. Although the marble staircase has many advantages, its shortcomings should also be pointed out: 1. First of all, in terms of price, marble is expensive. 2. Secondly, the marble stairs are often polished to make the surface smooth and beautiful, but this is also a double-edged knife, because the too delicate steps will become very slippery, so do anti-slip grooves. 3. Finally, marble is a very heavy material. Therefore, the marble staircase must ensure a solid and suitable understructure. 4. The marble internal staircase is suitable for any configuration, and the structure can take any form. If it is a spiral staircase, the marble is also fully adapted. Marble is the first choice for interior stairway decoration, because it exudes noble and elegant temperament all the time. The marble staircase is very beautiful and looks like a nobleman from a distant era, able to emphasize any style of decoration. Therefore, in addition to the special shape, the marble staircase will present a very attractive design, and marble is one of the most durable materials. Second, granite stairs Natural granite is igneous rock, also called acid crystalline plutonic rock. It is the most widely distributed rock in igneous rock and belongs to hard stone. The quality of granite depends on the mineral composition and structure, the granite with good quality, the crystal particles are fine and uniform, the mica content is less and the quartz is more, and it does not contain pyrite. Granite is not easy to weather and deteriorate, and its appearance and color can be kept for more than 100 years, so it is mostly used for wall foundation and ...

continue reading